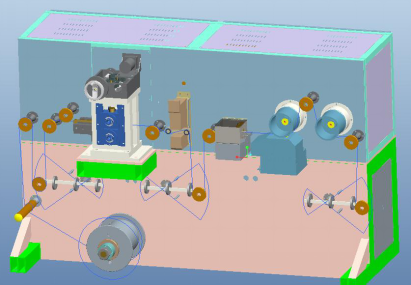

Finewire electrical---Rolling even with double double furnace

fineFlat line composite coating paint charter flightsdescribe

a、Characteristics of the equipment

1. The modular design, can be any combination;

2.High speed, precision rolling;

3. More stable quality performance;

(1) the stability of the enameled wire elongation is high;

(2) dimension control precision stability;

(3) the voltage is more stable;

(4) the material of many advantages such as higher yield.

4. More efficient production efficiency:

Threading consumed less working hours and reduce labor costs;

Large capacity pay-off reduced the pay-off in plate number;

Simplify the workersThe operation time and strength;

Disposable made of enameled wire and automatically change the plate of the widespread use of avoid waste in dish of enameled wire;

Through the PLC panel, length, weight can be automatically control in plate, avoid tail plate waste.

5, to adapt to the production of varieties:PIW, AIW, EI/AIW, EIW, SEIW, HBPIW, HBAIW Thermal level:180, 200, 220, 240

The second, the necessary material

1, all transmission adopts inverter control.

Frequency converter adopts: inovance brand;

Row line drive: the mitsubishi servo precision control system

2And the temperature control table adopts electricityAI-7048type4Road,PIDTemperature controller & SiemensPLCCommunication integration control, all integrated temperature display on the touch screen, touch screen using 3 d graphic displays each region, directly to see what is in the position of temperature;Temperature control components using thyristor;Temperature control over temperature alarm function, avoid big fault;Precision of the temperature controlPlus or minus 1℃。

3, the main electric components: all buttons, relays, all kinds of low voltage apparatus mostly use the well-known brands such as schneider.

4The tank adopts, baking furnace3-6mmHigh temperature resistant310 #Stainless steel plate, the highest temperature can reach900 ℃。

5Specially, annealing furnace tubes are forged310 #Stainless steel tube, inner surface finish0.6, the highest working temperature can be achieved750℃And outer diameter18mm。

6, idler pulley: front and rear wheel bracket combination idler pulley high strength aluminum alloy spraying ceramic, polished to a mirror;Line of single roller adopts imported nylon material.

7, all kinds of small small-sized bearing adoptsNMBorNSKBig brand, crossed the line roller adopts import double flanged edge bearing, rotating flexible, good stability and no shaking.

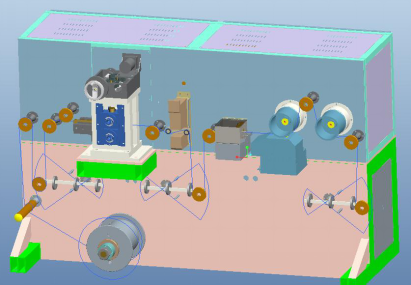

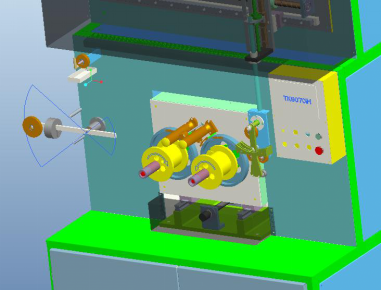

3, production lines,Main components:

Actively into the wire feeding systemeDouble roller precision rolling machineeContinuous control laser detection systemeMolding compression (with active traction)eAnnealing (including cleaning and dry)e Insulating paint paint chartereContinuous control laser detection systemeAdhesive layer of paint charter flightseContinuous control laser detection systemeThe line in full auto plate machine

Four, the main technical data:

|

Head | 2 head |

Oven Number | 2 |

The length of the oven | 3000mm、3600mm、4000mm、4500mm |

Range | The thickness of 0.03 mm to 0.6 mm, width is 0.30 mm to 6.0 mm |

Max speed | 150m/min |

Total passes

| Up to 24 / head |

|

|

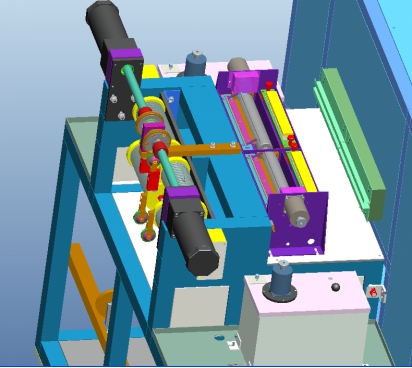

Actively taking part, rolling, molding compression (with active traction) |

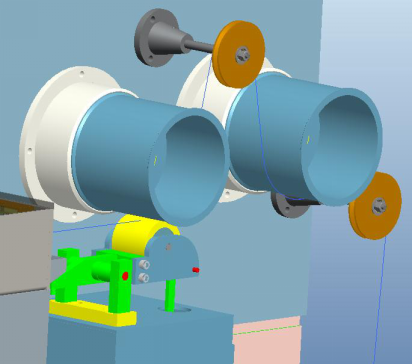

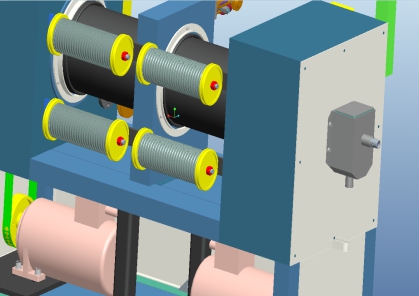

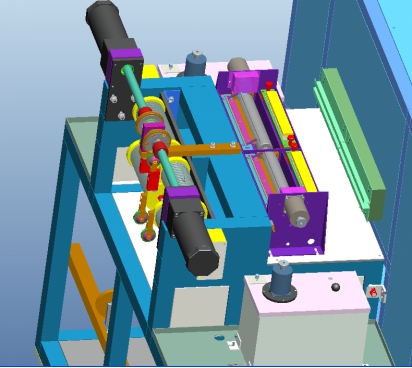

Active pay-off.Pay-off servo system;Swinging rod control constant tension;With caliper testing;Precision rolling;Roll diameter is 106 mm;Imported alloy production, military technology, high precision, long and durable;Line increase traction and qualify mold parts, ensure no burr flat wire conductor; |

|

|

|

Annealing, clean, dry, drying |

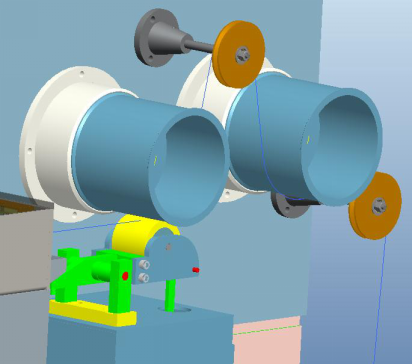

Annealing pipe 18 mm in diameter, length to 6 meters, large diameter, high temperature resistant to 750 degrees, a total of 2 root (spare another root), independent temperature control;The lining of polishing;2 degrees tilt Angle;Export direct water seal automatic heating generate steam anti-oxidation protection;Cleaning fluid weak acid formula;Felt after the outlet pipe to water + hot air blow dry;Export increase traction wheel (ensure that each part of the independent, non-slip, does not affect the tension of honest working procedure) |

|

|

|

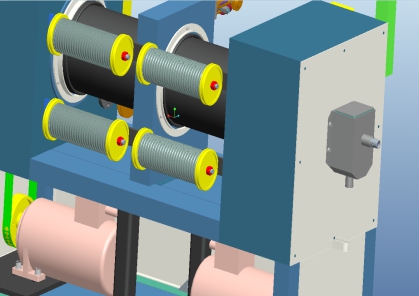

Paint drawing part |

Oven traction roller both sides independent control;200 mm in diameter, surface spraying ceramic polished to a mirror, to ensure sufficient traction non-slip does not damage the surface of the flat wire enameled at the same time;Up and down by two groups of composite roller line;Traction wheel circulating water cooling;Each of the traction wheel at most two lines |

|

|

|

Front wheel bracket and paint system |

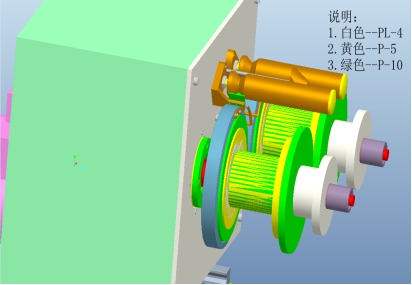

After the wheel frame is equipped with 2 sets of lacquer paint cylinder, a total of two stepper motors for high quality brand motor, speed can be adjusted by the controller, a rotational speed;Paint cylinder left and right sides can independently control;Paint way adopts double paint trough, double drum method, paint roller surface is equipped with scraper painting device (before and after independence for paint, paint back);Lacquer paint cylinder using felt and mold coating units, number of paint as two independent lacquer groove, each lacquer groove combined into 3 + 22 = 25, a total of 2 groups;Temperature control and automatic liquid level alarm;Adopts full stainless steel. |

|

|

|

Line spacing & idler pulley groove width | Line spacing: 6-12 mm;Roller bottom groove width: 1-8 mm |

Paint on the way | For paint roller + felt (automatic cycle, with automatic temperature control) |

Threading way | After the idler pulley wheel rack installation 1 set pressure device, lead wire around a way (threading with stainless steel belt). |

Temperature control system for paint | The paint paint and paint box has an automatic temperature control heating device Control constant temperature at about 50 degrees |

|

|

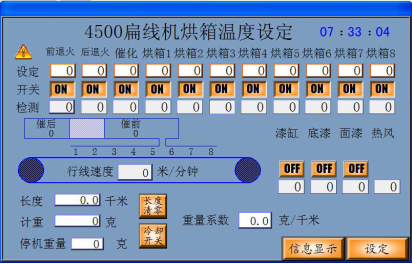

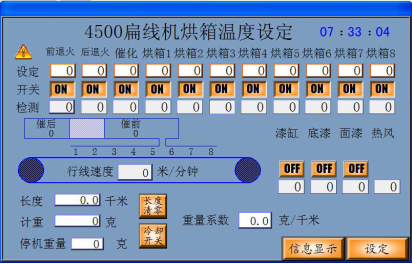

Oven temperature control |

Most can be set eight temperature control area;Speed display;To the length of the automatic plate change; |

|

Oven structure | 2 lines sharing a oven, middle separated, two lines per side Can make different specification products at the same time, with temperature) |

Oven, catalytic | Catalytic: adopt ceramic catalytic & heat exchange system (use of supplementary air heating); |

Oven adopts C (HC) new type catalytic combustion heat exchange;Oven catalysis using ceramic catalyst;Emissions from secondary catalytic, ensure the emissions standards prescribed by the state;The oven wall and catalytic chamber adopts 310 # stainless steel plate, high temperature resistance at 900 ℃;Oven of entrance and evaporation area, curing area, film forming area, export, catalytic before and after the catalytic a total of eight temperature control;Oven of the main loop (supplement) and exhaust fan, auxiliary fan made of 321 # stainless steel converter speed regulation;Furnace outlet air damper control, ensure enameled wire colour and lustre is consistent. |

With a total installed capacity | 46KW |

The power supply | 380V 50HZ |

Relative humidity | ≤70% |

The environment temperature | ≤45℃ |

|

|

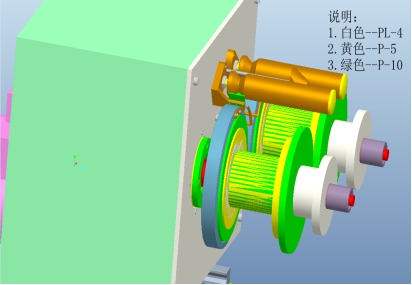

The metering roller and crossed the line |

Traction system actively, to ensure that each part of the tension control independently, to prevent the accumulation of tension wire elongation;High strength alloy, light weight, good heat dissipation;Fine polishing processing to mirror to ensure dynamic balance;To prevent wire drawing, jump line, etc.;Built-in import bearings, maintain a constant temperature, under the condition of high speed operation is good, durable |

|

|

|

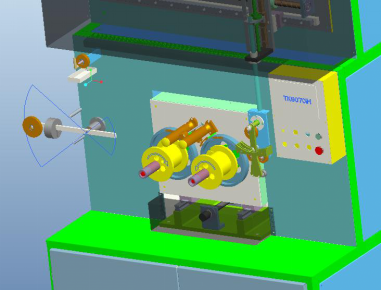

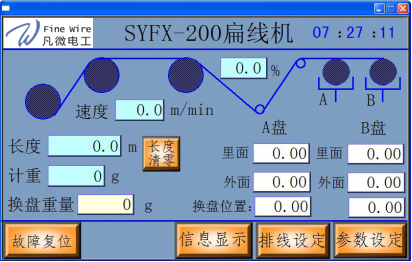

Collect, platoon line part |

Take-up using different plate position fixed way |

|

Swinging rod the line in constant tension control, automatic in plate, servo control precision shaft lift ribbon cable, wire wheel servo system design |

|

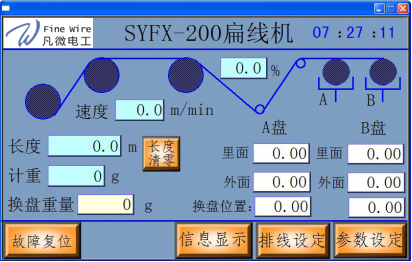

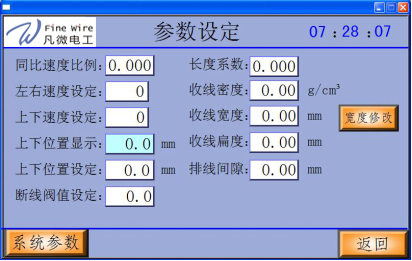

The line in the main screen |

|

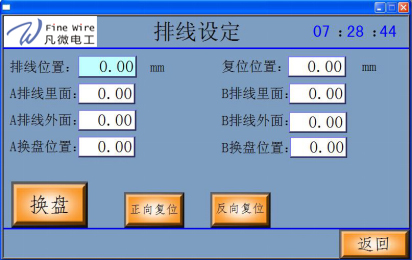

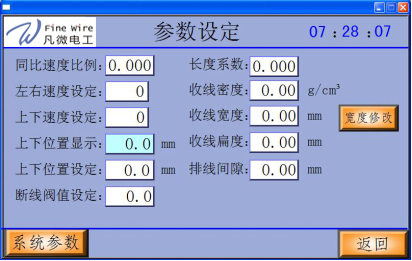

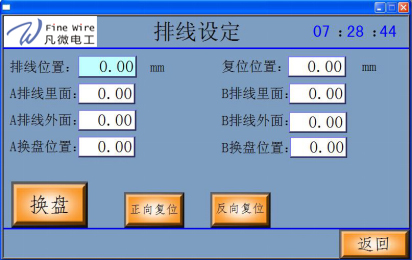

Take-up, platoon line parameter setting in detail |

|

In disc position setting, different coil is fine adjustment parameter; |

|

The take-up tension control | The line in swinging rod to control the constant tension control; |

Row spacing control | Automatic detection line, can the infinite set row spacing |

Wiring way | Shaft lift row line; |

In dish way | Double full auto plate. |

Receive coil | Available disc with: & PL PL - 4-10 |